2026.01.09

2026.01.09

Industry News

Industry News

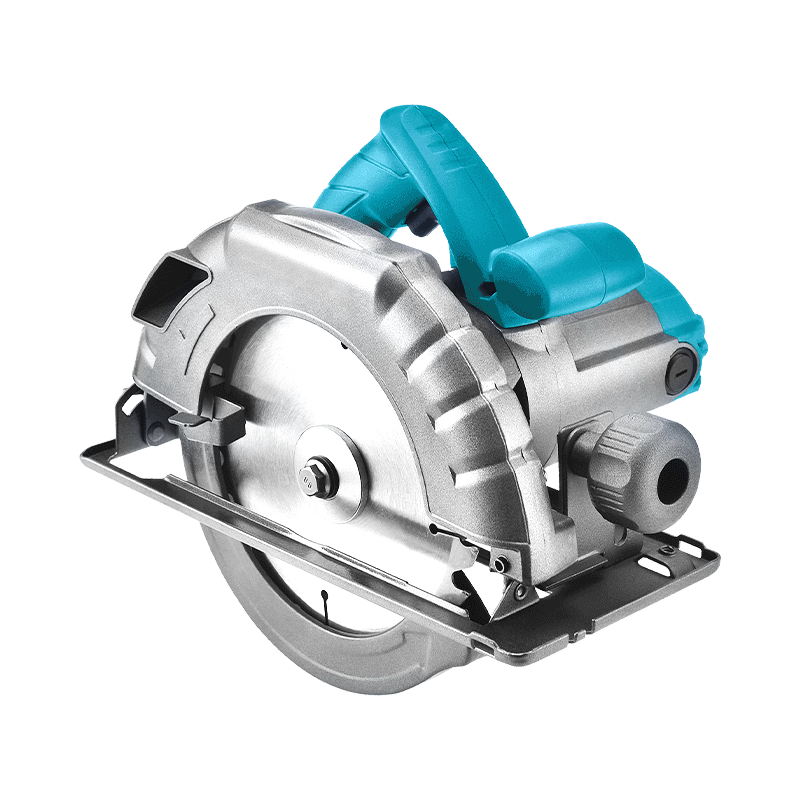

In the evolving landscape of power tools, one specialized instrument has steadily gained prominence for its ability to deliver both precision and adaptability in demanding cutting applications: the angle circular saw. This robust tool, distinguished by its capacity to make highly accurate bevel and miter cuts, is becoming an indispensable asset for professionals and advanced hobbyists across construction, woodworking, and fabrication industries. Unlike standard circular saws, the angle circular saw is engineered with advanced pivot and locking mechanisms that allow the blade to be tilted relative to the base plate, enabling clean angular cuts that are essential for complex joinery, trim work, and fitting tasks.

The defining feature of the angle circular saw lies in its precise angle adjustment system, which often includes clear, graduated scales and positive stops at common angles such as 22.5, 45, and 90 degrees. This design ensures repeatable accuracy, a critical factor when creating components that must fit together seamlessly, such as crown molding, picture frames, or custom cabinetry. Modern iterations of the angle circular saw incorporate enhancements like laser guides or LED shadow lines to project the exact cutting path onto the workpiece, significantly reducing measurement errors and material waste. Furthermore, many models now feature electric brakes that stop the blade rapidly after the trigger is released, contributing to a safer and more controlled working environment.

Power and performance remain central to the angle circular saw design. These tools typically house high-torque motors capable of maintaining consistent speed under load, allowing them to slice cleanly through dense hardwoods, engineered lumber, laminates, and non-ferrous metals. The integration of dust collection ports has also become more common, addressing the perennial issue of airborne particles and helping to maintain a clearer line of sight and a cleaner workspace. The development of brushless motor technology in some premium angle circular saw models offers improved efficiency, longer runtime, and reduced maintenance, making them suitable for sustained use on job sites and in workshops.

The versatility of the angle circular saw extends its utility beyond traditional woodworking. In metal fabrication, when equipped with an appropriate abrasive or carbide-tipped blade, it can accurately cut aluminum extrusions or steel tubing at precise angles for frames and structures. In renovation and remodeling, its ability to make tight, complex cuts in confined spaces proves invaluable for fitting materials around existing obstacles. The portable nature of a cordless angle circular saw, powered by modern lithium-ion battery platforms, has further expanded its on-site flexibility, allowing tradespeople to make precise cuts anywhere without searching for a power outlet.

The angle circular saw stands as a testament to the specialization within power tool design, addressing the nuanced need for angular precision in material cutting. Its evolution reflects a broader trend toward tools that offer not just power, but also intelligent features that enhance accuracy, safety, and efficiency. For any task demanding a cut that is not just straight, but precisely angled, the angle circular saw has firmly established itself as the instrument of choice, bridging the gap between raw material and refined craftsmanship with every controlled rotation of its blade.