2026.01.16

2026.01.16

Industry News

Industry News

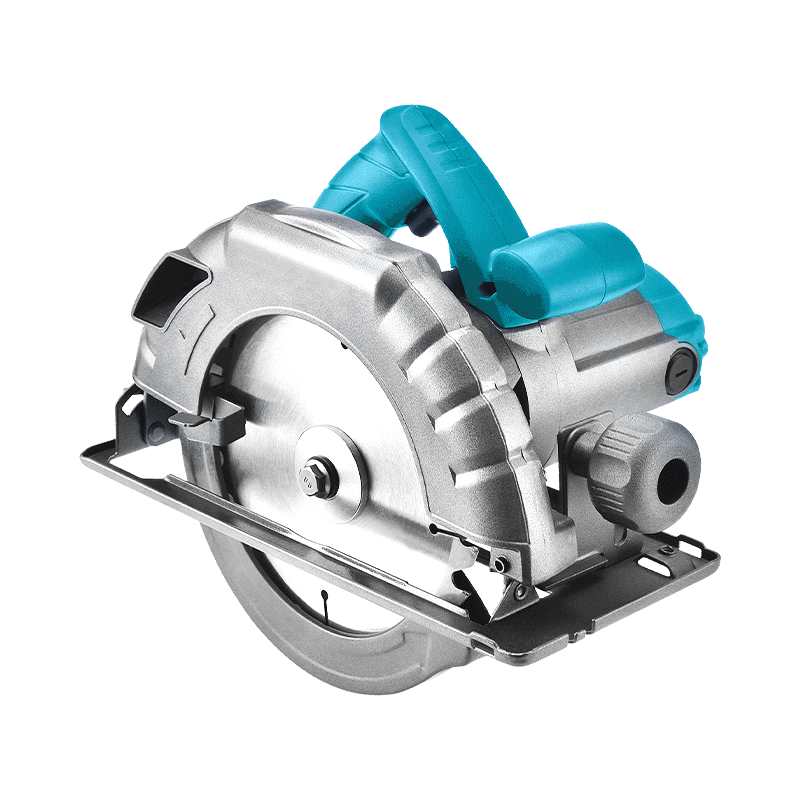

In workshops, construction sites, and DIY projects around the world, one tool has remained a cornerstone for efficient material cutting: the electric circular saw. This powerful handheld device, characterized by its toothed metal disc blade rotating at high speed, has evolved from a basic cutting instrument into a sophisticated piece of equipment that balances raw power with enhanced safety, precision, and user ergonomics. Its enduring relevance speaks to its fundamental role in transforming raw lumber, sheet goods, and other materials into precise components for building and fabrication.

The core function of the electric circular saw is to deliver fast, straight, and relatively clean cuts through a variety of materials. Powered by a compact yet high-torque electric motor, the saw drives its circular blade at speeds sufficient to slice cleanly through wood, plastics, laminates, and, with the appropriate blade, even metals like aluminum. The design of the electric circular saw typically features a base plate, or shoe, that rides along the workpiece, providing stability and allowing the user to guide the cut with accuracy. This combination of portability and power makes it indispensable for tasks ranging from framing a house to trimming shelving in a home renovation.

Technological advancements have significantly refined the modern electric circular saw. A key development is the widespread adoption of brushless motor technology. Compared to traditional brushed motors, brushless designs in an electric circular saw offer greater efficiency, longer runtime on battery-powered models, reduced maintenance, and often more power in a lighter package. Enhanced safety features have also become standard. Electric brakes, which stop the blade rapidly once the trigger is released, greatly reduce the risk of injury after a cut is completed. Riving knives, which help prevent kickback by keeping the kerf open, and blade guards that retract automatically during cutting are critical safety components integrated into the design of a responsible electric circular saw.

Ergonomics and ease of use are now major focuses for manufacturers. Modern electric circular saw designs feature improved balance to reduce user fatigue, better positioned handles for control, and clear line-of-sight cutting guides. The rise of the cordless electric circular saw, powered by high-capacity lithium-ion battery platforms, has granted users exceptional freedom of movement on job sites without the hassle and potential hazard of a power cord. These cordless models now rival the power of their corded counterparts for common applications, further cementing their popularity among both professionals and serious hobbyists.

The utility of the electric circular saw is further extended by its compatibility with a vast array of specialized blades. By simply changing the blade, a single electric circular saw can be optimized for ripping lumber, cross-cutting plywood, making fine finish cuts, or even cutting masonry with an abrasive diamond blade. This versatility makes it a highly adaptable tool. Furthermore, accessories like guide rails or laser guides can be attached to many models, enabling long, superbly straight cuts with professional-level accuracy, rivaling some stationary saws for precision on sheet goods.

The electric circular saw exemplifies the democratization of powerful fabrication technology. It puts rapid, precise cutting capability directly into the hands of the user, enabling everything from large-scale construction to detailed craft projects. Its continuous refinement—prioritizing safety, ergonomics, and cordless convenience—ensures that this classic tool will remain a vital and dynamic force in the toolkit of builders, makers, and craftspeople for the foreseeable future, continuing to shape the built environment one precise cut at a time.